The Rise of Robot Vacuum Cleaners in Industrial Settings

In recent years, the landscape of industrial cleaning has actually seen a considerable change with the intro of robot vacuum. These automated gadgets are not simply a novelty for homes; they have actually acquired traction in warehouses, manufacturing plants, and other industrial environments. This post explores the functionality, benefits, and considerations of robot vacuum cleaners within the industrial context, while answering some often asked questions.

What are Robot Vacuum Cleaners?

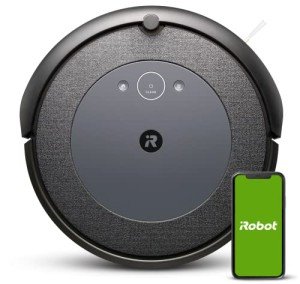

Robot vacuum cleaners are automated cleaning devices equipped with advanced sensing units and innovation that enable them to navigate around areas, identify dirt, and vacuum surfaces without direct human intervention. In industrial settings, they are created to handle a range of particles types, help with regular cleaning schedules, and enhance general operational efficiency.

Table 1: Key Features of Industrial Robot Vacuum Cleaners

| Feature | Description |

|---|---|

| Navigation | Uses LiDAR or camera-based navigation for precise mapping. |

| Size and Design | Compact and robust style to suit tight areas and endure hard environments. |

| Self-Charging | Immediately returns to its docking station for recharging. |

| Dustbin Capacity | Bigger dustbin suited for industrial particles sizes and volumes. |

| Shows | Can be configured for scheduling and specific cleaning tasks. |

| Information Collecting | Equipped with sensors to collect data for maintenance and cleaning analysis. |

Benefits of Robot Vacuum Cleaners in Industrial Settings

The adoption of robot best smart vacuum cleaners features a myriad of advantages:

Increased Efficiency:

- 24/7 Operation: Unlike human cleaners, robots can run around the clock, adding to continuous cleanliness without downtime.

- Time-Saving: Automated cleaning allows staff members to focus on core jobs rather than cleaning responsibilities.

Expense Savings:

- Labor Costs: Maintaining a robot best automatic vacuum can lower the need for a large cleaning personnel, decreasing general labor expenses.

- Operational Efficiency: With enhanced cleanliness and lowered downtime due to maintenance problems, organizations can minimize operational expenses.

Enhanced Safety:

- Reduced Risk: By minimizing the human involvement in harmful cleaning environments, the risk of mishaps is minimized.

- Constant Cleaning: Robot vacuums make sure that locations are regularly cleaned up, decreasing slip threats and unhealthy environments.

Increased Flexibility:

- Customizable Cleaning Routes: These makers can be configured to tidy particular areas or floorings, adapting to altering industrial designs.

- Range of Surfaces: Industrial robot Cleaning machine vacuums can manage various automatic floor cleaners covering types, from concrete to tiles, making them flexible.

Ecological Impact:

- Sustainable Cleaning Solutions: Many models utilize minimal water and eco-friendly cleaning services, helping in business sustainability efforts.

Table 2: Industrial Applications of Robot Vacuum Cleaners

| Market | Application |

|---|---|

| Production | Cleaning production lines and assembly areas. |

| Warehousing | Preserving clean and organized storage areas. |

| Food Processing | Guaranteeing cleanliness in sensitive locations to meet health standards. |

| Pharmaceuticals | Preserving ultra-clean environments for production. |

| Logistics and Distribution | Keeping paths clear for efficient operation. |

Difficulties and Considerations

While the benefits are significant, businesses should also consider numerous obstacles:

- Initial Investment: The upfront costs of acquiring industrial robot vacuum can be significant, though long-term savings might offset this expense.

- Upkeep and Repairs: Regular upkeep is important to keep the robotic vacuums systems operating optimally, and repair work can incur additional expenses.

- Integration: Businesses may need to integrate these devices into existing workflows, which can need time and modification.

- Training and Support: Staff might need training to efficiently handle these devices, especially when troubleshooting or programs is needed.

FAQs About Robot Vacuum Cleaners in Industrial Settings

1. How much do industrial robot broom vacuum cost?

The cost can range from a few thousand to tens of countless dollars, depending upon specs, features, and brand.

2. What kinds of surfaces can they clean up?

Robot vacuum appropriate for numerous surfaces including carpets, tiles, concrete, and even some wooden floors.

3. How do they browse intricate industrial environments?

Most industrial robot vacuums use sophisticated navigation systems like LiDAR, video cameras, and sensors to map out and adjust to their surroundings for efficient cleaning.

4. Can they clean up large areas without human intervention?

Yes, industrial robot vacuums are designed to tidy comprehensive locations with pre-programmed routes and schedules, efficiently operating autonomously.

5. Are these robots eco-friendly?

Lots of designs focus on efficiency and minimize water usage, making them a more ecologically friendly cleaning choice compared to standard techniques.

The intro of robot vacuum into industrial environments signifies an impressive improvement in cleaning technology. With their ability to enhance performance, reduce labor expenses, and keep safety, these automated systems are leading the way for smarter and cleaner industrial operations. While challenges might exist, the long-lasting benefits and technological advancements are motivating for industries seeking to enhance their cleaning protocols. As technology continues to develop, we can anticipate further innovations in robot vacuum that will transform industrial cleaning practices much more.

📌 Avoid Making This Fatal Mistake When It Comes To Your Robot Vacuum Cleaner

📌 Avoid Making This Fatal Mistake When It Comes To Your Robot Vacuum Cleaner